|

|||||||||||||||

Все документы, представленные в каталоге, не являются их официальным изданием и предназначены исключительно для ознакомительных целей. Электронные копии этих документов могут распространяться без всяких ограничений. Вы можете размещать информацию с этого сайта на любом другом сайте.

Федеральный горный и промышленный надзор России

(Госгортехнадзор России)

Серия 28

Неразрушающий контроль

Выпуск 4

СИСТЕМА

НЕРАЗРУШАЮЩЕГО КОНТРОЛЯ

ВИДЫ (МЕТОДЫ) И ТЕХНОЛОГИЯ

НЕРАЗРУШАЮЩЕГО КОНТРОЛЯ

ТЕРМИНЫ И ОПРЕДЕЛЕНИЯ

Справочное пособие

Москва

Государственное унитарное предприятие «Научно-технический центр по безопасности в промышленности Госгортехнадзора России»

Ответственные составители-разработчики:

П.П. Бирюкова (разделы 1, 2), В.П. Вавилов (раздел 12), В.А. Воронков (разделы 1, 2, 4), Ю.А. Глазков (раздел 7), А.И. Евлампиев (раздел 8), В.Г. Засецкий (раздел 11), В.И. Иванов (разделы 1, 2, 3, 9, 10, 12), Н.Н. Коновалов (разделы 1, 2), Ю.В. Ланге (раздел 4), Л.А. Соколова (раздел 6), Ф.Р. Соснин (разделы 3, 10, 12), М.В. Филинов (раздел 6), В.Е. Шатерников (раздел 5), В.П. Шевченко (разделы 1, 2), Г.С. Шелихов (раздел 7)

Система неразрушающего контроля. Виды (методы) и технология неразрушающего контроля. Термины и определения: Справочное пособие. Серия 28. Выпуск 4 / Колл.авт. - М.: Государственное унитарное предприятие «Научно-технический центр по безопасности в промышленности Госгортехнадзора России», 2003.

В настоящее Справочное пособие включены термины и определения по видам (методам) неразрушающего контроля, по которым проводится аттестация в Системе неразрушающего контроля Госгортехнадзора России, а также по общим вопросам неразрушающего контроля.

Справочное пособие предназначено для специалистов в области неразрушающего контроля и смежных областях. Оно может быть использовано при разработке стандартов, методической и другой технической документации по неразрушающему контролю, при написании статей, книг и других материалов. Может оказаться полезным при переводе текстов с русского языка на английский и с английского на русский.

Государственное унитарное предприятие «Научно-технический центр по безопасности в промышленности Госгортехнадзора России» (ГУП «НГЦ «Промышленная безопасность») - официальный издатель нормативных документов Госгортехнадзора России (приказ Госгортехнадзора России от 19.03.01 № 32)

СОДЕРЖАНИЕ

ВВЕДЕНИЕ

Неразрушающий контроль (НК) является важнейшим элементом системы экспертизы промышленной безопасности, обеспечивающей техническую безопасность на опасном производственном объекте. За последние годы НК, выполняя важную функцию в указанной системе, развивается ускоренными темпами во всех своих составляющих, включая развитие новых методов и методик, создание более совершенной техники, базирующейся на достижениях электроники и вычислительных устройств, повышение требований к персоналу в области НК.

Развитие НК нашло свое отражение и в появлении новых терминов, которые используются в практике, научных трудах и технических описаниях. НК во все большей степени контактирует со смежными направлениями, участвующими в оценке реального технического состояния объектов, определении возможности их дальнейшей эксплуатации и сроков безопасной работы (проблема ресурса). К таким направлениям относятся металловедение, механика разрушения (расчеты прочности), теория надежности и другие разделы науки и техники. Все это способствует появлению в области НК новых понятий и соответственно новых терминов. В НК традиционно используются термины и определения, соответствующие другим областям знаний, например физике, прикладной математике, радиоэлектронике, метрологии, которые также нуждаются в систематизации и уточнении.

Терминология, включающая термины и определения, в значительной степени отражает уровень соответствующих видов деятельности. НК в настоящее время находится на очередном этапе скачкообразного развития. Перед ним стоят задачи не только сбора информации о наличии или отсутствии дефектов в контролируемом объекте, но и задачи измерения параметров обнаруженных дефектов в целях определения влияния дефектов на прочность объекта, на возможность его безопасной эксплуатации.

Термин - это слово или словосочетание, являющееся точным названием, обозначающим некоторое понятие науки и техники, характеризующееся устойчивой однозначностью и определенностью.

Определение - это раскрытие содержания термина (понятия), объяснение его значения (смысла, содержания). При формулировании определения, как правило, перечисляются не все признаки, а только отличительные, существенные, наиболее полно раскрывающие содержание термина.

В рамках дальнейшего развития Системы НК было принято решение о создании терминологического документа (справочного пособия) в области НК, в котором бы нашли отражение процессы обновления и развития всех методов НК. Потребность в таком документе связана также с приходом в НК большого количества новых людей, для которых знакомство с терминологией может явиться элементом вхождения в профессию и получения образовательной информации.

Разработанный документ состоит из следующих разделов:

1. Общие термины и определения.

2. Общие термины по неразрушающему контролю.

3. Радиационный неразрушающий контроль.

4. Акустический неразрушающий контроль.

5. Вихретоковый неразрушающий контроль.

6. Контроль проникающими веществами (капиллярный).

7. Магнитный неразрушающий контроль.

8. Контроль проникающими веществами (течеискание).

9. Акустико-эмиссионный неразрушающий контроль.

10. Оптический, визуальный и измерительный неразрушающий контроль.

11. Вибрационный неразрушающий контроль.

12. Тепловой неразрушающий контроль.

Каждая терминологическая статья состоит из термина, его английского эквивалента (перевода на английский язык), обозначения (если оно имеется) и определения термина. В конце словарной статьи приведен источник, как правило, это стандарт (российский или международный). В ряде случаев в терминологической статье приведено примечание, разъясняющее или дополняющее определение термина. В конце некоторых разделов приведены списки источников. Кроме того, каждый раздел содержит алфавитный список терминов.

В тех случаях, когда термины связаны с физической величиной, единицы измерения даны в Международной системе единиц (СИ).

Каждый раздел обсуждался на заседаниях соответствующих секций Совета экспертов по НК. Разработчики с благодарностью примут замечания и предложения по содержанию, которые будут учтены в следующих изданиях Справочного пособия.

1. ОБЩИЕ ТЕРМИНЫ И ОПРЕДЕЛЕНИЯ

Безопасность

1.1. Безопасность труда (Safety of a transactions) - состояние условий труда, при котором исключено воздействие на работающих опасных и вредных производственных факторов [1].

1.2. Безопасность производственного оборудования (Safety of an industrial equipment) - свойство производственного оборудования сохранять соответствие требованиям безопасности труда при выполнении заданных функций в условиях, установленных нормативно-технической документацией [1].

1.3. Техника безопасности (Safety precautions) - система организационных мероприятий и технических средств, предотвращающих воздействие на работающих опасных производственных факторов [1].

1.4. Промышленная безопасность опасных производственных объектов (Industrial safety of hazardous production facilities) - состояние защищенности жизненно важных интересов личности и общества от аварий на опасных производственных объектах и последствий указанных аварий [2].

1.5. Экспертиза промышленной безопасности (Industrial safety expertise) - оценка соответствия объекта экспертизы предъявляемым к нему требованиям промышленной безопасности, результатом которой является заключение [3].

1.6. Объекты экспертизы (Objects of expertise) - проектная документация, технические устройства, здания и сооружения на опасном производственном объекте, декларации промышленной безопасности и иные документы, связанные с эксплуатацией опасного производственного объекта [3].

1.7. Экспертная организация (Expert organisation) - организация, имеющая лицензию Госгортехнадзора России на проведение экспертизы промышленной безопасности в соответствии с действующим законодательством [3].

1.8. Эксперт (Expert) - специалист, осуществляющий проведение экспертизы промышленной безопасности [3].

1.9. Качество (Quality) - совокупность свойств и характеристик продукции или услуги, которые придают им способность удовлетворять обусловленные или предполагаемые потребности [4].

1.10. Нормативные показатели качества (НПК) (Normative parameters of quality) - показатели соответствия объекта контроля предъявляемым ему техническим требованиям.

1.11. Технологический процесс (Technological process) - часть производственного процесса, содержащая целенаправленные действия по изменению (или) определению состояния предмета труда [5].

1.12. Производственный процесс (Production) - совокупность всех действий людей и орудий труда, необходимых на данном предприятии для изготовления и ремонта продукции [6].

1.13. Работоспособное состояние (Up state) - состояние объекта контроля, при котором значение всех параметров, характеризующих способность выполнять заданные функции, соответствует требованиям нормативной технической документации и (или) конструкторской (проектной) документации [7].

1.14. Промышленная катастрофа (Industrial catastrophe) - крупная промышленная авария, повлекшая за собой человеческие жертвы, ущерб здоровью людей либо разрушение и уничтожение объектов, материальных ценностей в значительных размерах, а также приведшая к серьезному ущербу окружающей природной среде [8].

1.15. Авария (Accident) - разрушение сооружений и (или) технических устройств, применяемых на опасном производственном объекте, неконтролируемые взрыв и (или) выброс опасных веществ [2].

1.16. Инцидент (Incident) - отказ или повреждение технических устройств, применяемых на опасном производственном объекте, отклонение от режима технологического процесса, нарушение положений федеральных законов и иных нормативных правовых актов Российской Федерации, а также нормативных технических документов, устанавливающих правила ведения работ на опасном производственном объекте [2].

1.17. Нештатная ситуация (Unnominal situation) - ситуация, при которой технологический процесс или состояние оборудования выходит за рамки нормального функционирования и может привести к аварии [9].

1.18. Отказ (Failure) - событие, заключающееся в нарушении работоспособного состояния объекта [7].

1.19. Сбой (Refusal) - самоустраняющийся отказ или однократный отказ, устраняемый незначительным вмешательством оператора [7].

1.20. Критерий отказа (Failure criterion) - признак или совокупность признаков нарушения работоспособного состояния объекта, установленные в нормативной технической документации и (или) конструкторской (проектной) документации [7].

1.21. Предельное состояние (Limiting condition) - состояние объекта контроля, при котором его дальнейшая эксплуатация недопустима или нецелесообразна либо восстановление его работоспособного состояния невозможно или нецелесообразно [7].

1.22. Критерий предельного состояния (Criterion of a limiting condition) - совокупность признаков, при которых использование технического устройства по назначению должно быть прекращено (или невозможно) и оно должно направляться на капитальный ремонт или сниматься с эксплуатации [7]*.

* Здесь и далее по тексту знак * означает: «Определение соответствующего термина скорректировано относительно определения, данного в соответствующем источнике».

1.23. Срок службы (Lifetime) - календарная продолжительность эксплуатации от начала эксплуатации объекта или ее возобновление после ремонта до перехода в предельное состояние [7].

1.24. Остаточный ресурс (Residual life) - суммарная наработка объекта от момента контроля его технического состояния до перехода в предельное состояние [7].

Техническая документация

1.25. Нормативный технический документ (Technical standard) - документ, устанавливающий правила, общие принципы или характеристики, касающиеся различных видов деятельности или их результатов [10]*.

Примечание. Под документом следует понимать любой носитель с записанной в нем или на его поверхности информацией.

1.26. Техническое условие (Specification) - документ, устанавливающий технические требования, которым должна удовлетворять продукция, процесс или услуга [10].

1.27. Стандарт (Standard) - документ, в котором в целях добровольного многократного использования устанавливаются характеристики продукции, правила осуществления и характеристики процессов производства, эксплуатации, хранения, перевозки, реализации и утилизации, выполнения работ или оказания услуг. Стандарт также может содержать требования к терминологии, символике, упаковке, маркировке или этикеткам и правилам их нанесения [15].

1.28. Национальный стандарт (National standard) - стандарт, принятый национальным органом по стандартизации и доступный широкому кругу пользователей [10].

1.29. Государственный стандарт Российской Федерации (State standard of Russian Federation) - национальный стандарт, принятый федеральным органом исполнительной власти по стандартизации или федеральным органом исполнительной власти по строительству [10].

1.30. Межгосударственный стандарт (International standard) - региональный стандарт, принятый государствами, присоединившимися к Соглашению о проведении согласованной политики в области стандартизации, метрологии и сертификации [10].

1.31. Стандарт отрасли (Branch standard) - стандарт, принятый федеральным органом исполнительной власти в пределах его компетенции [10].

1.32. Стандарт предприятия (Standard of the enterprise) - стандарт, принятый субъектом хозяйствования [10].

1.33. Гармонизированные стандарты (Harmonized standards) - стандарты, принятые различными занимающимися стандартизацией органами, распространяющиеся на одни и те же объекты стандартизации и обеспечивающие взаимозаменяемость продукции, процессов и услуг и взаимное понимание результатов испытаний или информации, представляемой в соответствии с этими стандартами [10].

1.34. Унифицированные стандарты (Unified standards) - гармонизированные стандарты, которые идентичны по содержанию и по форме представления [10].

1.35. Идентичные стандарты (Identical standards) - гармонизированные стандарты, которые идентичны по содержанию, но не идентичны по форме представления [10].

1.36. Сертификат соответствия (Certificate of conformance) - документ, выданный в соответствии с правилами системы сертификации и удостоверяющий, что должным образом идентифицированная продукция, процесс или услуга соответствуют конкретному стандарту или другому нормативному документу [10].

1.37. Положение - логическая единица содержания нормативного документа, которая имеет форму сообщения, инструкции, рекомендации или требования [10].

1.38. Инструкция (Instruction) - положение, описывающее действие, которое должно быть выполнено [10].

1.39. Рекомендация (Recommendation) - положение, содержащее совет [10].

1.40. Требование - положение, содержащее критерии, которые должны быть соблюдены [10].

1.41. Методическое положение - положение, указывающее один или несколько способов достижения соответствия требованию нормативного документа [10].

1.42. Регламент - документ, который принят международным договором Российской Федерации, ратифицированным в порядке, установленном законодательством Российской Федерации, или федеральным законом, или указом Президента Российской Федерации, или постановлением Правительства Российской Федерации и устанавливает обязательные для применения и исполнения требования к объектам технического регулирования (продукции, в том числе зданиям, строениям и сооружениям, процессам производства, эксплуатации, хранения, перевозки, реализации и утилизации) [15].

1.43. Технический регламент (Technical rules) - регламент, содержащий технические требования либо непосредственно, либо путем ссылки на стандарт, технические условия или кодекс установившейся практики, либо путем включения в себя содержания этих документов [10].

1.44. Кодекс установившейся практики - документ, рекомендующий практические правила или процедуры проектирования, изготовления, монтажа, технического обслуживания или эксплуатации оборудования, конструкций или изделий [10].

1.45. Правила по стандартизации [метрологии, сертификации, аккредитации] - нормативный документ, устанавливающий обязательные для применения организационно-технические и (или) общетехнические положения, порядки, методы выполнения работ по стандартизации [метрологии, сертификации, аккредитации], а также рекомендуемые правила оформления результатов этих работ [10].

1.46. Рекомендации по стандартизации [метрологии, сертификации, аккредитации] - нормативный документ, содержащий добровольные для применения организационно-технические и (или) общетехнические положения, порядки, методы выполнения работ по стандартизации [метрологии, сертификации, аккредитации], а также рекомендуемые правила оформления результатов этих работ [10].

1.47. Срок действия нормативного документа - интервал времени, в течение которого действует нормативный документ, начиная от даты введения его в действие в соответствии с решением ответственного за это органа до момента его отмены или замены [10].

Смежные виды деятельности

1.48. Техническая диагностика (Technical diagnostics) - область знаний, охватывающая теорию, методы и средства определения технического состояния объектов [11].

1.49. Техническое диагностирование (Technical diagnosis) - определение технического состояния объекта [11].

1.50. Диагностический (контролируемый) параметр (Test parameter) - параметр объекта, используемый при его диагностировании (контроле) [11].

1.51. Техническое состояние объекта (Technical condition of an object) - состояние, которое характеризуется в определенный момент времени, при определенных условиях внешней среды значениями параметров, установленных технической документацией на объект [11].

1.52. Контроль технического состояния (Testing condition, inspection) - проверка соответствия значений параметров объекта требованиям технической документации и определение на этой основе одного из заданных видов технического состояния в данный момент времени [11].

Примечание. Видами технического состояния являются, например, исправное, работоспособное, неисправное, неработоспособное и т.п. в зависимости от значений параметров в данный момент времени [11].

1.53. Прогнозирование технического состояния (Technical condition prediction) - определение технического состояния объекта с заданной вероятностью на предстоящий интервал времени [11].

1.54. Измерение (Measurement) - нахождение значения физической величины опытным путем с помощью специальных технических средств [12].

1.55. Средство измерений (Measuring equipment) - техническое устройство, предназначенное для измерений [13].

1.56. Калибровка средств измерений (Calibration) - совокупность операций, выполняемых в целях определения и подтверждения действительных значений метрологических характеристик и (или) пригодности к применению средств измерений, не подлежащих государственному метрологическому контролю и надзору [13].

1.57. Поверка средств измерений (Government inspection) - совокупность операций, выполняемых органом государственной метрологической службы или другими уполномоченными на то органами (организациями), с целью определения и подтверждения соответствия средств измерений установленным техническим требованиям [13].

1.58. Испытание (Test) - экспериментальное определение количественных и (или) качественных характеристик свойств объекта испытаний как результата воздействия на него при его функционировании, при моделировании объекта и (или) воздействий [10].

1.59. Программа испытаний (Test program) - организационно-методический документ, устанавливающий объект и цели испытаний, виды, последовательность и объем проводимых экспериментов, порядок, условия, место и сроки проведения испытаний, обеспечение и отчетность по ним, ответственность за обеспечение и проведение испытаний [14]*.

Алфавитный список терминов раздела 1

Авария (Accident) 1.15

Безопасность производственного оборудования (Safety of an industrial equipment) 1.2

Безопасность труда (Safety of a transactions) 1.1

Гармонизированные стандарты (Harmonized standards) 1.33

Государственный стандарт Российской Федерации

(State standard of Russian Federation) 1.29

Диагностический (контролируемый) параметр (Test parameter) 1.50

Идентичные стандарты (Identical standards) 1.35

Измерение (Measurement) 1.54

Инструкция (Instruction) 1.38

Инцидент (Incident) 1.16

Испытание (Test) 1.58

Калибровка средств измерений (Calibration) 1.56

Качество (Quality) 1.9

Кодекс установившейся практики 1.44

Контроль технического состояния (Testing condition, inspection) 1.52

Критерий отказа (Failure criterion) 1.20

Критерий предельного состояния (Criterion of a limiting condition) 1.22

Межгосударственный стандарт (International standard) 1.30

Методическое положение 1.41

Национальный стандарт (National standard) 1.28

Нештатная ситуация (Unnominal situation) 1.17

Нормативные показатели качества (НПК) (Normative parameters of quality) 1.10

Нормативный технический документ (Technical standard) 1.25

Объекты экспертизы (Objects of expertise) 1.6

Остаточный ресурс (Residual life) 1.24

Отказ (Failure) 1.18

Поверка средств измерений (Government inspection) 1.57

Положение 1.37

Правила по стандартизации [метрологии, сертификации, аккредитации] 1.45

Предельное состояние (Limiting condition) 1.21

Прогнозирование технического состояния (Technical condition prediction) 1.53

Программа испытаний (Test program) 1.59

Производственный процесс (Production) 1.12

Промышленная безопасность опасных производственных объектов

(Industrial safety of hazardous production facilities) 1.4

Промышленная катастрофа (Industrial catastrophe) 1.14

Работоспособное состояние (Up state) 1.13

Регламент 1.42

Рекомендации по стандартизации [метрологии, сертификации, аккредитации] 1.46

Рекомендация (Recommendation) 1.39

Сбой (Refusal) 1.19

Сертификат соответствия (Certificate of conformance) 1.36

Средство измерений (Measuring equipment) 1.55

Срок действия нормативного документа 1.47

Срок службы (Lifetime) 1.23

Стандарт (Standard) 1.27

Стандарт отрасли (Branch standard) 1.31

Стандарт предприятия (Standard of the enterprise) 1.32

Техника безопасности (Safety precautions) 1.3

Техническая диагностика (Technical diagnostics) 1.48

Технический регламент (Technical rules) 1.43

Техническое диагностирование (Technical diagnosis) 1.49

Техническое состояние объекта (Technical condition of an object) 1.51

Техническое условие (Specification) 1.26

Технологический процесс (Technological process) 1.11

Требование 1.40

Унифицированные стандарты (Unified standards) 1.34

Эксперт (Expert) 1.8

Экспертиза промышленной безопасности (Industrial safety expertise) 1.5

Экспертная организация (Expert organisation) 1.7

Источники терминов и определений раздела 1

1. ГОСТ 12.0.002-80. Система стандартов безопасности труда. Термины и определения.

2. Федеральный закон «О промышленной безопасности опасных производственных объектов» от 21.07.97 № 116-ФЗ.

3. Правила проведения экспертизы промышленной безопасности (ПБ 03-246-98), утверждены постановлением Госгортехнадзором России от 06.11.98 № 64.

4. ИСО 8402. Управление качеством и обеспечение качества: Словарь. ISO 8402:1994 (E/F/R).

5. ГОСТ 3.1109-82 ЕСТД. Термины и определения. Основные понятия.

6. ГОСТ 14.004-83. Технологическая подготовка производства. Термины и определения основных понятий.

7. ГОСТ 27.002-89. Надежность в технике. Основные понятия. Термины и определения.

8. ГОСТ Р 22.0.05 БЧС. Типичные чрезвычайные ситуации. Термины и определения.

9. Общие правила взрывобезопасности для взрывопожароопасных химических, нефтехимических и нефтеперерабатывающих производств (ПБ 09-170-97), утверждены постановлением Госгортехнадзора России 22.12.97 № 52.

10. ГОСТ Р 1.12-99. Стандартизация и смежные виды деятельности. Термины и определения.

11. ГОСТ 20911-89. Техническая диагностика. Термины и определения.

12. ГОСТ 16263-70. Метрология. Термины и определения.

13. Федеральный закон «Об обеспечении единства измерений» от 27.04.93 № 4871-1.

14. ГОСТ 16504-81. Система государственных испытаний продукции. Испытания и контроль качества продукции. Основные термины и определения.

15. Федеральный закон «О техническом регулировании» от 27.12.02 № 184-ФЗ (Собрание законодательства Российской Федерации. № 52. Ч. 1. Ст. 5140).

2. ОБЩИЕ ТЕРМИНЫ ПО НЕРАЗРУШАЮЩЕМУ КОНТРОЛЮ

2.1. Неразрушающий контроль (NDT) - контроль, при котором не должна быть нарушена пригодность технических устройств, зданий и сооружений к применению и эксплуатации [1].

2.2. Система неразрушающего контроля (NDT system) - совокупность участников, которые в рамках регламентирующих норм, правил, методик, условий, критериев и процедур осуществляют деятельность в области одного из видов экспертизы промышленной безопасности, связанной с применением НК [2].

2.3. Результат неразрушающего контроля (Outcome of NDT) - установленная оценка соответствия объекта контроля предъявляемым ему техническим требованиям, понимаемая как результат сопоставления окончательной информации об объекте контроля с требованиями нормативных технических документов.

2.4. Объект неразрушающего контроля (Object of NDT) - техническое устройство, здание или сооружение, подвергаемое неразрушающему контролю.

2.5. Объем неразрушающего контроля (Amount of NDT) - характеристика неразрушающего контроля, определяемая количеством (в том числе и в размерных единицах: длиной, площадью, объемом) объектов и применяемых видов (методов) контроля.

2.6. Метод неразрушающего контроля (NDT method) - метод контроля, при котором не должна быть нарушена пригодность объекта к применению, основанный на том или ином физическом явлении [3, 5]*.

2.7. Вид неразрушающего контроля (Kind of NDT) - условная группировка методов неразрушающего контроля, объединенная общностью физических характеристик [3].

Примечание. Виды неразрушающего контроля классифицируются по следующим классификационным признакам:

а) по характеру физических полей или излучений, взаимодействующих с контролируемым объектом;

б) по характеру взаимодействия физических полей или веществ с контролируемым объектом;

в) по первичным информативным параметрам;

г) по способам индикации первичной информации;

д) по способу представления окончательной информации.

2.8. Контролепригодность (Suitability to testing) - свойство объекта НК, обеспечивающее возможность, удобство и надежность его контроля на всех стадиях жизненного цикла [4]*.

2.9. Производственный неразрушающий контроль (NDT during manufacturing) - контроль, осуществляемый на стадии изготовления объекта [5]*.

2.10. Эксплуатационный неразрушающий контроль (In service NDT) - контроль, осуществляемый на стадии эксплуатации объекта [5]*.

2.11. Входной неразрушающий контроль (NDT on an input) - контроль объекта, поступившего к потребителю или заказчику [5]*.

2.12. Операционный неразрушающий контроль (NDT on operations) - контроль объекта во время выполнения или после завершения технологической операции [5]*.

2.13. Приемочный неразрушающий контроль (Acceptance NDT) - контроль объекта, по результатам которого принимается решение о его пригодности к поставке и (или) использованию [5]*.

2.14. Сплошной неразрушающий контроль (Full volume NDT) - контроль каждой единицы продукции в партии [5]*.

2.15. Выборочный неразрушающий контроль (Selective NDT) - контроль, при котором решение о контролируемой совокупности объектов или процессе принимают по результатам проверки одной или нескольких выборок [6]*.

2.16. Измерительный контроль (Measuring NDT) - контроль, осуществляемый с применением средств измерений [5]*.

2.17. Средство неразрушающего контроля (Equipment of NDT and technical diagnostics) - техническое устройство, вещество, материал, программный продукт, используемые для получения и обработки информации об объекте для проведения НК.

2.18. Методический документ по неразрушающему контролю (Test procedure) - организационно-методический документ, включающий объекты контроля, вид контроля, метод контроля, средства и условия контроля, алгоритмы выполнения операций по определению одной или нескольких взаимосвязанных характеристик свойств объекта, формы представления данных и оценивания точности, достоверности результатов, требований техники безопасности и охраны окружающей среды [5]*.

2.19. Технологическая инструкция по неразрушающему контролю (Technological procedure of NDT) - документ, ориентированный на решение задачи неразрушающего контроля конкретного объекта с указанием операций контроля и их параметров.

2.20. Технологическая карта неразрушающего контроля (Technological flow chart of NDT) - документ в виде карты (таблицы), содержащий основные данные технологической инструкции.

2.21. Заключение по результатам НК (NDT conclusion) - документ, составленный по результатам НК, содержащий информацию о выполненном контроле и его результатах.

2.22. Основные параметры неразрушающего контроля (Main parameters of NDT) - совокупность параметров неразрушающего контроля, обеспечивающих выполнение установленных нормативной технической документацией требований по обнаружению дефектов, измерению параметров дефектов и оценке влияния дефектов на объект.

2.23. Достоверность неразрушающего контроля (Reliability of NDT) - показатель неразрушающего контроля (количественный или качественный), связанный с вероятностями принятия безошибочных решений о наличии или отсутствии дефектов.

2.24. Дефектометрия (Sizing) - измерение параметров дефектов.

2.25. Реальная чувствительность (Real sensitivity) - наименьшие размеры реального дефекта, обнаруживаемого в объекте контроля.

Примечание. Реальная чувствительность определяется на основании сравнения результатов НК и вскрытия реальных объектов контроля.

2.26. Перебраковка (Over reject) - результат контроля, при котором годный объект контроля признается браком.

2.27. Недобраковка (Missing) - результат контроля, при котором бракованный объект признается годным.

2.28. Основные параметры контроля (Main testing parameters) - совокупность параметров контроля, обусловливающих его достоверность.

2.29. Пространственное разрешение (Spatial resolution) - способность надежно различать близко расположенные дефекты [4]*.

2.30. Отношение сигнал / шум (Signal to noise ratio) - отношение амплитуды (или энергии) сигнала, создаваемого дефектом в материале, к среднеквадратическому значению сигнала (или энергии) шума [4]*.

2.31. Лаборатория НК (NOT firm) - организация (предприятие), одним из видов деятельности которой является осуществление НК, или подразделение организации (предприятия), применяющее НК технических устройств, зданий и сооружений для собственных нужд [1].

2.32. Специалист в области неразрушающего контроля (NDT employee) - специалист (сотрудник), допущенный к выполнению неразрушающего контроля технических устройств, зданий и сооружений на опасных производственных объектах.

2.33. Независимый орган по аттестации (Independent agency) - организация, уполномоченная в рамках Системы экспертизы промышленной безопасности проводить аттестацию персонала, лабораторий, средств в области НК.

2.34. Аттестация персонала (Personnel certification) - процесс подтверждения Независимым органом квалификации и соответствия компетентности кандидата требованиям Правил аттестации персонала в области неразрушающего контроля (ПБ 03-440-02) по какому-либо виду (методу) неразрушающего контроля в соответствующей области аттестации [7].

2.35. Квалификация (Qualification) - соответствие определенным требованиям, таким, как образование, профессиональные знания, навыки и опыт, которые дают возможность специалисту профессионально выполнять неразрушающий контроль [7].

2.36. Квалификационное удостоверение (Qualifying certificate) - документ, выдаваемый Независимым органом, удостоверяющий, что специалист компетентен в осуществлении неразрушающего контроля одним или несколькими видами (методами) неразрушающего контроля в определенной области аттестации в соответствии с присвоенным уровнем квалификации [7].

Дефекты

Общая характеристика дефектов

2.37. Дефект (Defect) - каждое отдельное несоответствие продукции требованиям, установленным нормативной документацией [4].

2.38. Брак (Rejected part) - объект контроля, содержащий недопустимый дефект.

2.39. Недопустимый дефект (Rejected defect) - дефект, не соответствующий требованиям, установленным нормативной документацией.

2.40. Дефектный объект (Defective item) - изделие, имеющее хотя бы один дефект [8]*.

2.41. Явный дефект (Obvious defect) - дефект, для выявления которого в нормативной документации, обязательной для данного вида контроля, предусмотрены соответствующие правила, методы и средства [8].

2.42. Скрытый дефект (Latent defect) - дефект, для выявления которого в нормативной документации, обязательной для данного вида контроля, не предусмотрены соответствующие правила, методы и средства [4].

2.43. Критический дефект (Critical defect) - дефект, при наличии которого использование продукции по назначению практически невозможно или недопустимо [8].

2.44. Значительный дефект (Significant defect) - дефект, который существенно влияет на использование продукции по назначению и (или) на ее долговечность, но не является критическим [8].

2.45. Малозначительный дефект (Insignificant defect) - дефект, который существенно не влияет на использование продукции по назначению и ее долговечность [8].

2.46. Устранимый дефект (Corrected defect) - дефект, устранение которого технически возможно и экономически целесообразно [8].

2.47. Неустранимый дефект (Incorrigible defect) - дефект, устранение которого технически невозможно или экономически нецелесообразно [8].

2.48. Индикация дефекта (Defect indication) - изображение или сигнал от дефекта в форме, типичной для используемого вида (метода) НК [4]*.

2.49. Обнаружение дефекта (Defect detection) - определение наличия дефекта [4]*.

2.50. Оценка дефекта (Defect evaluation) - оценка параметров дефекта, выявленного НК, в сравнении с установленным уровнем [4]*.

2.51. Ложная индикация (False indication) - индикация, не соответствующая реальному дефекту [4]*.

2.52. Регистрация (Recording) - запись результатов контроля в форме, пригодной для обработки и хранения [4]*.

2.53. Несплошность (Discontinuity) - нарушение однородности материала, вызывающее скачкообразное изменение одной или нескольких физических характеристик - плотности, магнитной проницаемости, скорости звука, волнового сопротивления и т.п.

Примечание. Примеры несплошностей: трещины, шлаковые включения, непровары, раковины и т.п.

К дефектам, не являющимся несплошностями, относятся, например, отклонения физико-механических свойств материалов от допустимых значений (например, пониженная прочность или твердость), изменение размеров и формы.

Дефекты сварных соединений

2.54. Кратер (Crater) - углубление, образующееся в конце валика под действием давления дуги и объемной усадки металла шва [9].

2.55. Трещина сварного соединения (Crack) - дефект сварного соединения в виде разрыва в сварном шве и (или) прилегающих к нему зонах [9].

2.56. Разветвленная трещина сварного соединения (Branched crack) - трещина сварного соединения, имеющая ответвления в различных направлениях [9].

2.57. Усадочная раковина сварного шва (Shrinkage cavity) - дефект в виде полости или впадины, образованный при усадке металла шва в условиях отсутствия питания жидким металлом [9].

2.58. Вогнутость корня шва (Root concavity) - дефект в виде углубления на поверхности обратной стороны сварного одностороннего шва [9].

2.59. Свищ в сварном шве (Worm-hole) - дефект в виде воронкообразного углубления в сварном шве [9].

2.60. Пора в сварном шве (Gas pore) - дефект сварного шва в виде полости округлой формы, заполненной газом [9].

2.61. Цепочка пор в сварном шве (Linear porosity) - группа пор в сварном шве, расположенных в линию [9].

2.62. Непровар (Lack of fusion) - дефект в виде несплавления в сварном соединении вследствие неполного расплавления кромок или поверхностей ранее выполненных валиков сварного шва [9].

2.63. Прожог сварного шва (Burn-through) - дефект в виде сквозного отверстия в сварном шве, образовавшийся в результате вытекания части металла сварочной ванны [9].

2.64. Шлаковое включение сварного шва (Slag inclusion) - дефект в виде вкрапления шлака в сварном шве [9].

2.65. Неметаллическое включение сварного шва (Non-metal inclusion) - дефект в виде неметаллической частицы в металле шва [9].

2.66. Брызги металла (Spatters) - дефект в виде затвердевших капель на поверхности сварного соединения [9].

2.67. Подрез зоны сплавления (Undercut) - дефект в виде углубления по линии сплавления сварного шва с основным металлом [9].

2.68. Наплыв на сварном соединении (Overlap) - дефект в виде натекания металла шва на поверхность основного металла или ранее выполненного валика без сплавления с ним [9].

2.69. Смещение сваренных кромок (Edge displacement) - неправильное положение сваренных кромок друг относительно друга [9].

Дефекты литья

2.70. Горячая трещина (Hot crack) - дефект в виде разрыва или надрыва тела отливки усадочного происхождения, возникшего в интервале температур затвердевания [10].

2.71. Холодная трещина (Cold crack) - дефект в виде разрыва тела затвердевшей отливки вследствие внутренних напряжений или механического воздействия [10].

2.72. Межкристаллическая трещина (Intergranular crack) - дефект в виде разрыва тела отливки при охлаждении отливки в форме на границе первичных зерен аустенита в температурном интервале распада [10].

2.73. Газовая раковина (Blowhole) - дефект в виде полости, образованной выделившимися из металла или внедрившимися в металл газами [10].

2.74. Усадочная раковина (Draw, contraction cavity) - дефект в виде открытой или закрытой полости с грубой шероховатой, иногда окисленной поверхностью, образовавшейся вследствие усадки при затвердевании металла [10].

2.75. Рыхлота (Microporosity) - дефект в виде скопления мелких усадочных раковин [10].

2.76. Отбел (Chill hard spots) - дефект в виде твердых, трудно поддающихся механической обработке мест в различных частях отливки из серого чугуна, вызванных скоплением структурно-свободного цементита [10].

2.77. Половинчатость (Mottleness) - дефект в виде проявления структуры серого чугуна в отливках из белого чугуна [10].

2.78. Флокен (Flakes) - дефект в виде разрыва тела отливки под влиянием растворенного в стали водорода и внутренних напряжений, проходящего полностью или частично через объемы первичных зерен аустенита [10].

Дефекты ковки и проката

2.79. Волосовина (Hairline, spill) - дефект поверхности в виде нитевидных неровностей в металле, образовавшихся при деформации имеющихся в нем неметаллических включений [11].

2.80. Расслоение (Delamination) - дефект поверхности в виде трещин на кромках и торцах листов и других видов проката, образовавшихся при наличии в металле усадочных дефектов, внутренних разрывов, повышенной загрязненности неметаллическими включениями и при пережоге [11].

2.81. Слиточная плена (Sliver, rolled scab) - дефект поверхности в виде отслоения языкообразной формы, частично соединенного с основным металлом, образовавшегося от раската окисленных брызг, заплесков и грубых неровностей поверхности слитка, обусловленных дефектами внутренней поверхности изложницы [11].

2.82. Прокатная плена (Sliver, rolled skin) - дефект поверхности, представляющий собой отслоение металла языкообразной формы, соединенное с основным металлом одной стороной, образовавшееся вследствие раскатки или расковки рванин, подрезов, следов глубокой зачистки дефектов или сильной выработки валков, а также грубых механических повреждений [11].

2.83. Ус (Ridge) - дефект поверхности, представляющий собой продольный выступ с одной или двух диаметрально противоположных сторон прутка, образовавшийся вследствие неправильной подачи металла в калибр, переполнения калибра или неправильной настройки валков и привалковой арматуры [11].

2.84. Подрез - дефект поверхности в виде углубления, расположенного по всей длине или на отдельных участках проката и образовавшийся вследствие неправильной настройки привалковой арматуры или одностороннего перекрытия калибра [11].

2.85. Закат (Lap) - дефект поверхности, представляющий собой прикатанный продольный выступ, образовавшийся в результате закатывания уса, подреза, грубых следов зачистки и грубых рисок [11].

2.86. Заков (Forging fold) - дефект поверхности, представляющий собой придавленный выступ, образовавшийся при ковке в результате неравномерного обжатия [11].

2.87. Риска (Groove, guide mark) - дефект поверхности в виде канавки без выступа кромок с закругленным или плоским дном, образовавшийся от царапания поверхности металла изношенной прокатной арматурой [11].

Дефекты механической обработки

2.88. Заусенец (Burr) - дефект поверхности, представляющий собой острый, в виде гребня, выступ, образовавшийся при резке металла [11].

2.89. Зазубрины (Hacks) - дефект поверхности в виде выступов и углублений на кромках листа и ленты, образовавшихся при нарушении технологии резки или неисправности оборудования [11].

2.90. Шлифовочные трещины (Grinding cracks) - дефект поверхности в виде сетки паутинообразных или отдельных, произвольно направленных поверхностных разрывов, образовавшихся при шлифовании или абразивной зачистке металла, обладающего высокой твердостью, хрупкостью и малой теплопроводимостью [11].

2.91. Вмятины (Compression marks) - дефект поверхности в виде произвольно расположенных углублений различной формы, образовавшихся вследствие повреждений и ударов поверхности при транспортировке, правке, складировании и других операциях [11].

2.92. Царапина (Scratch) - дефект поверхности, представляющий собой углубление неправильной формы и произвольного направления, образующееся в результате механических повреждений, в том числе при складировании и транспортировке металла [11].

Алфавитный список терминов раздела 2

Аттестация персонала (Personnel certification) 2.34

Брак (Rejected part) 2.38

Брызги металла (Spatters) 2.66

Вид неразрушающего контроля (Kind of NDT) 2.7

Вмятины (Compression marks) 2.91

Вогнутость корня шва (Root concavity) 2.58

Волосовина (Hairline, spill) 2.79

Входной неразрушающий контроль (NDT on an input) 2.11

Выборочный неразрушающий контроль (Selective NDT) 2.15

Газовая раковина (Blowhole) 2.73

Горячая трещина (Hot crack) 2.70

Дефект (Defect) 2.37

Дефектный объект (Defective item) 2.40

Дефектометрия (Sizing) 2.24

Достоверность неразрушающего контроля (Reliability of NDT) 2.23

Зазубрины (Hacks) 2.89

Закат (Lap) 2.85

Заключение по результатам HK (NDT conclusion) 2.21

Заков (Forging foid) 2.86

Заусенец (Burr) 2.88

Значительный дефект (Significant defect) 2.44

Измерительный контроль (Measuring NDT) 2.16

Индикация дефекта (Defect indication) 2.48

Квалификационное удостоверение (Qualifying certificate) 2.36

Квалификация (Qualification) 2.35

Контролепригодность (Suitability to testing) 2.8

Кратер (Crater) 2.54

Критический дефект (Critical defect) 2.43

Лаборатория HK (NDT firm) 2.31

Ложная индикация (False indication) 2.51

Малозначительный дефект (Insignificant defect) 2.45

Межкристаллическая трещина (Intergranular crack) 2.72

Метод неразрушающего контроля (NDT method) 2.6

Методический документ по неразрушающему контролю (Test procedure) 2.18

Наплыв на сварном соединении (Overlap) 2.68

Недобраковка (Missing) 2.27

Недопустимый дефект (Rejected defect) 2.39

Независимый орган по аттестации (Independent agency) 2.33

Неметаллическое включение сварного шва (Non-metal inclusion) 2.65

Непровар (Lack of fusion) 2.62

Неразрушающий контроль (NDT) 2.1

Несплошность (Discontinuity) 2.53

Неустранимый дефект (Incorrigible defect) 2.47

Обнаружение дефекта (Defect detection) 2.49

Объект неразрушающего контроля (Object of NDT) 2.4

Объем неразрушающего контроля (Amount of NDT) 2.5

Операционный неразрушающий контроль (NDT on operations) 2.12

Основные параметры контроля (Main testing parameters) 2.28

Основные параметры неразрушающего контроля (Main parameters of NDT) 2.22

Отбел (Chill hard spots) 2.76

Отношение сигнал / шум (Signal to noise ratio) 2.30

Оценка дефекта (Defect evaluation) 2.50

Перебраковка (Over reject) 2.26

Подрез 2.84

Подрез зоны сплавления (Undercut) 2.67

Половинчатость (Mottleness) 2.77

Пора в сварном шве (Gas pore) 2.60

Приемочный неразрушающий контроль (Acceptance NDT) 2.13

Прожог сварного шва (Burn-through) 2.63

Производственный неразрушающий контроль (NDT during manufacturing) 2.9

Прокатная плена (Sliver, rolled skin) 2.82

Пространственное разрешение (Spatial resolution) 2.29

Разветвленная трещина сварного соединения (Branched crack) 2.56

Расслоение (Delamination) 2.80

Реальная чувствительность (Real sensitivity) 2.25

Регистрация (Recording) 2.52

Результат неразрушающего контроля (Outcome of NDT) 2.3

Риска (Groove, guide mark) 2.87

Рыхлота (Microporosity) 2.75

Свищ в сварном шве (Worm-hole) 2.59

Система неразрушающего контроля (NDT system) 2.2

Скрытый дефект (Latent defect) 2.42

Слиточная плена (Sliver, rolled seab) 2.81

Смещение сваренных кромок (Edge displacement) 2.69

Специалист в области неразрушающего контроля (NDT employee) 2.32

Сплошной неразрушающий контроль (Full volume NDT) 2.14

Средство неразрушающего контроля (Equipment of NDT and technical diagnostics) 2.17

Технологическая инструкция по неразрушающему контролю

(Technological procedure of NDT) 2.19

Технологическая карта неразрушающего контроля

(Technological flow chart of NDT) 2.20

Трещина сварного соединения (Crack) 2.55

Ус (Ridge) 2.83

Усадочная раковина (Draw, contraction cavity) 2.74

Усадочная раковина сварного шва (Shrinkage cavity) 2.57

Устранимый дефект (Corrected defect) 2.46

Флокен (Flakes) 2.78

Холодная трещина (Cold crack) 2.71

Царапина (Scratch) 2.92

Цепочка пор в сварном шве (Linear porosity) 2.61

Шлаковое включение сварного шва (Slag inclusion) 2.64

Шлифовочные трещины (Grinding cracks) 2.90

Эксплуатационный неразрушающий контроль (In service NDT) 2.10

Явный дефект (Obvious defect) 2.41

Источники терминов и определений раздела 2

1. Положение о Независимом органе по аттестации лабораторий неразрушающего контроля // Система неразрушающего контроля. Аттестация лабораторий: Сборник документов. Серия 28. Выпуск 1. 2-е изд., испр. и доп. М.: Государственное унитарное предприятие «Научно-технический центр по безопасности в промышленности Госгортехнадзора России», 2002. 104 с.

2. Правила аттестации и основные требования к лабораториям неразрушающего контроля (ПБ 03-372-00). Положение о Системе неразрушающего контроля // Система неразрушающего контроля. Аттестация лабораторий: Сборник документов. Серия 28. Выпуск 1. 2-е изд., испр. и доп. М.: Государственное унитарное предприятие «Научно-технический центр по безопасности в промышленности Госгортехнадзора России», 2002. 104 с.

3. ГОСТ 18353-73. Контроль неразрушающий. Классификация методов.

4. Неразрушающий контроль. Россия, 1900-2000 гг.: Справочник / В.В. Клюев, Ф.Р. Соснин, С.В. Румянцев и др.; Под ред. В.В. Клюева. М.: Машиностроение, 2001. 616 с.

5. ГОСТ 16504-81. Система государственных испытаний продукции. Испытания и контроль качества продукции. Основные термины и определения.

6. ИСО 8402. Управление качеством и обеспечение качества: Словарь. ISO 8402:1994 (E/F/R).

7. Положение о Независимом органе по аттестации персонала в области неразрушающего контроля // Система неразрушающего контроля. Аттестация персонала: Сборник документов. Серия 28. Выпуск 3. М.: Государственное унитарное предприятие «Научно-технический центр по безопасности в промышленности Госгортехнадзора России», 2002. 120 с.

8. ГОСТ 15467-79. Управление качеством продукции. Основные понятия. Термины и определения.

9. ГОСТ 2601-84. Сварка металлов. Термины и определения основных понятий.

10. ГОСТ 19200-80. Отливки из чугуна и стали. Термины и определения дефектов.

11. ГОСТ 21014-88. Прокат черных металлов. Термины и определения дефектов поверхности.

3. РАДИАЦИОННЫЙ НЕРАЗРУШАЮЩИЙ КОНТРОЛЬ

3.1. Радиационный неразрушающий контроль (Radiation nondestructive testing) - вид НК, основывающийся на регистрации и анализе ионизирующего излучения после взаимодействия с контролируемым объектом.

Примечания: 1. Промышленная радиология (Industrial radiology) - наука и применение рентгеновского и гамма-излучения, нейтронов и другого проникающего излучения в неразрушающем контроле.

2. В наименовании методов контроля, приборов, характеристик и т. п. слово «радиационный» может заменяться словом, обозначающим конкретный вид ионизирующего излучения (например, рентгеновский, нейтронный и т.п.).

3.2. Ионизирующее излучение - излучение, взаимодействие которого со средой приводит к образованию ионов разных знаков.

Примечание. Общепринято видимый свет и ультрафиолетовое излучение не включать в понятие «ионизирующее излучение».

3.3. Непосредственно ионизирующее излучение - ионизирующее излучение, состоящее из заряженных частиц, имеющих кинетическую энергию, достаточную для ионизации при столкновении.

Примечание. Непосредственно ионизирующее излучение может состоять из электронов, протонов, альфа-частиц и др.

3.4. Косвенно ионизирующее излучение - ионизирующее излучение, состоящее из незаряженных частиц, которые могут создавать непосредственно ионизирующее излучение и (или) вызывать ядерные превращения.

Примечание. Косвенно ионизирующее излучение может состоять из нейтронов, фотонов и др.

3.5. Первичное ионизирующее излучение - ионизирующее излучение, которое в рассматриваемом процессе взаимодействия со средой является или принимается исходным.

3.6. Первичное излучение (Primary radiation) - излучение, проходящее непосредственно вдоль прямой линии от источника излучения к детектору без отклонения.

3.7. Вторичное ионизирующее излучение - ионизирующее излучение, возникающее в результате взаимодействия первичного ионизирующего излучения с рассматриваемой средой.

3.8. Рентгеновское излучение (X-rays) - проникающее электромагнитное излучение с примерным диапазоном длин волн 1-0,0001 нм, генерированное при бомбардировке высокоскоростными электронами металлической мишени.

3.9. Рассеянное излучение (Scattered radiation) - излучение, изменившее направление распространения с изменением или без изменения энергии при прохождении вещества.

3.10. Качество излучения (Quality of beam of radiation) - проникающая способность излучения, часто измеряемая слоем половинного ослабления.

3.11. Коэффициент накопления (Build-up factor) - отношение интенсивности всего излучения, достигающего некоторой точки, к интенсивности первичного излучения, достигающего той же точки.

3.12. Комптоновское рассеяние (Compton scatter) - вид рассеяния фотона рентгеновского или гамма-излучения, взаимодействующего с электроном и теряющего часть энергии.

Примечание. Для излучения в диапазоне энергии от 100 кэВ до 10 МэВ комптоновское рассеяние является основным фактором ослабления излучения.

3.13. Активация - процесс, в результате которого материал, подвергнутый бомбардировке нейтронами или другими частицами, становится радиоактивным.

3.14. Узкий пучок ионизирующего излучения (Narrow beam of ionizing radiation) - ионизирующее излучение, состоящее до взаимодействия со средой из первично направленного излучения, а после взаимодействия с ней - из части первичного излучения, не испытавшего взаимодействия со средой.

3.15. Широкий пучок ионизирующего излучения (Broad beam of ionizing radiation) - ионизирующее излучение, состоящее до взаимодействия со средой из первично направленного излучения, а после взаимодействия с ней - из части первичного излучения, не испытавшего взаимодействия со средой, и рассеянного излучения.

3.16. Коэффициент накопления ионизирующего излучения (Build-up of ionizing radiation) - отношение значения физического параметра (плотности потока энергии, мощности дозы и т. д.) широкого пучка к соответствующему значению параметра узкого пучка в определенной точке после взаимодействия направленного первичного ионизирующего излучения со средой.

3.17. Источник излучения (Radiation source) - оборудование (например, рентгеновская трубка или источник гамма-излучения), способное эмитировать ионизирующее излучение.

3.18. Радиограмма (Radiograph) - изображение, видимое после обработки, созданное проникающим ионизирующим излучением на радиографической пленке или бумаге. Этот термин также используется для изображений, созданных нейтронами, электронами, протонами и т.д.

3.19. Активность (Activity) - количество распадов ядер в единицу времени в радиоактивном источнике.

3.20. Радиационная толщина (Radiation thickness) - суммарная длина участков оси рабочего пучка направленного первичного ионизирующего излучения в материале контролируемого объекта.

3.21. Ослабление (Attenuation) - уменьшение интенсивности рентгеновского или гамма-излучения при его прохождении через вещество за счет поглощения и рассеяния.

3.22. Слой половинного ослабления (Half value thickness) - толщина конкретного материала, который, будучи введен в пучок рентгеновского или гамма-излучения, уменьшает его интенсивность в два раза.

3.23. Коэффициент ослабления μ (Attenuation coefficient μ) - соотношение между интенсивностью (I0) излучения, падающего на одну сторону поглощающего вещества, и интенсивностью прошедшего через вещество излучения (I) при толщине поглощающего вещества (t), определяемое как I=I0 ехр(-μt).

3.24. Поглощение (Absorption) - процесс, в котором количество падающих фотонов уменьшается при прохождении вещества.

3.25. Средний градиент (Average gradient) - наклон линии, проведенной между двумя определенными точками на сенситометрической кривой.

3.26. Рабочий пучок ионизирующего излучения - пространственно ограниченная часть потока первичного излучения, предназначенная для практического применения.

3.27. Неиспользуемое ионизирующее излучение - первичное ионизирующее излучение вне границ рабочего пучка ионизирующего излучения.

3.28. Ось рабочего пучка ионизирующего излучения - ось симметрии рабочего пучка ионизирующего излучения.

Примечание. В [2] ось падающего излучения (Incident beam axis) - ось конусного пучка излучения, определяемая фокальным пятном и окном трубки.

3.29. Фокусное пятно (Focal spot) - область на аноде рентгеновской трубки, эмитирующая рентгеновское излучение, наблюдаемая с измерительного устройства.

3.30. Размер фокусного пятна (Focal spot size) - размер по фокусному пятну рентгеновской трубки, измеренный параллельно плоскости пленки или флюоресцирующего экрана.

3.31. Эффективное фокусное пятно источника ионизирующего излучения (Effective focal spot of ionizing radiation source) - проекция излучающей области источника ионизирующего излучения на плоскость, перпендикулярную оси рабочего пучка ионизирующего излучения.

3.32. Расстояние «фокус-пленка» [Focus-to-film distance (ffd)] - кратчайшее расстояние от фокуса рентгеновской трубки до пленки при радиографической экспозиции.

Примечание. В [2] используется также термин «расстояние «источник-пленка» (Source-to-film distance) - расстояние между источником излучения и пленкой, измеренное в направлении распространения излучения.

3.33. Расстояние «объект-пленка» (Object-to-film distance) - расстояние между облучаемой стороной контролируемого объекта и поверхности пленки, измеренное вдоль центральной оси пучка излучения.

3.34. Радиационное изображение (Radiation image) - изображение, сформированное ионизирующим излучением в результате его взаимодействия с контролируемым объектом.

3.35. Теневое радиационное изображение (Shadow radiation image) - радиационное изображение за контролируемым объектом, сформированное широким или узким пучком ионизирующего излучения.

3.36. Световое изображение (Light image) - изображение, сформированное видимым излучением, непосредственно воспринимаемое глазом человека.

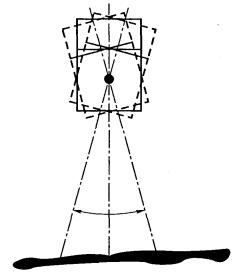

3.37. Панорамная экспозиция (Panoramic exposure) - радиографический аппарат, использующий свойства источника гамма-излучения эмитировать излучение по всем направлениям, или панорамная рентгеновская установка, например, для одновременного радиографирования нескольких образцов или для облучения окружности цилиндрического образца.

3.38. Радиографический снимок (Radiogram) - распределение плотности почернения или цвета на рентгеновской и фотопленке, коэффициента отражения света на ксерографическом снимке и т.п., соответствующее радиационному изображению контролируемого объекта.

3.39. Оптическая плотность вуали (Fog density) - общий термин, используемый для обозначения оптической плотности обрабатываемой пленки, создаваемой причиной, отличной от непосредственного формирования изображения. Такими причинами могут быть старение, химическое воздействие, дихроизм, собственная вуаль, посторонняя экспозиция.

3.40. Экспозиция (Exposure) - процесс, при котором излучение регистрируется на системе получения изображения.

3.41. Калькулятор экспозиции (Exposure calculator) - устройство (например, линейка со скользящим движком), которое может быть использовано для определения требуемого времени экспозиции.

3.42. Таблица экспозиций (Exposure chart) - таблица, показывающая уровень радиографических экспозиций для различных толщин конкретного материала и для данного качества излучения.

3.43. Широта экспозиции (Exposure latitude) - диапазон экспозиции, соответствующий полезному диапазону оптической плотности снимка.

3.44. Длительность экспозиции (Exposure time) - продолжительность процесса экспонирования излучением регистрирующего материала.

3.45. Характеристическая кривая (пленки) [Charasteristic curve (of a film)] - кривая, показывающая соотношение между десятичным логарифмом экспозиции lg К и оптической плотностью D.

3.46. Радиографическая пленка (Radiographic film) - пленка, содержащая прозрачную подложку, обычно покрытую с обеих сторон эмульсией, чувствительной к излучению.

3.47. Подложка пленки (Film base) - несущий материал, на который нанесена фоточувствительная эмульсия.

3.48. Пленка для работы с экраном (Screen type film) - радиографическая пленка, предназначенная для использования с флюоресцентными усиливающими экранами.

3.49. Время осветления (Clearing time) - длительность первого этапа закрепления пленки, в течение которого исчезает вуаль.

3.50. Градиент пленки (G) [Film gradient (G)] - наклон характеристической кривой пленки при конкретной оптической плотности D.

3.51. Полезный диапазон оптических плотностей (Useful density range) - диапазон оптических плотностей радиограммы, используемый для интерпретации изображения. Верхний предел определяется освещением негатоскопа, а нижний предел - потерей чувствительности обнаружения дефекта.

3.52. Вуаль старения (Ageing fog) - увеличение оптической плотности неэкспонированной пленки, измеренной после обработки, обусловленное длительным хранением.

3.53. Угол падения излучения (Beam angle) - угол между центральной осью пучка излучения и плоскостью пленки.

3.54. Преобразователь радиационного изображения (Radiation image converter) - устройство для преобразования радиационного изображения в изображение другого вида.

3.55. Радиационно-оптический преобразователь изображения (Radiation-optical image converter) - устройство для преобразования радиационного изображения в световое изображение.

3.56. Собственная фильтрация (Inherent filtration) - фильтрация излучения частями рентгеновской трубки, установки или контейнера источника излучения, через которые проходит первичное излучение.

3.57. Нерезкость (Unsharpness) - потеря разрешения изображения из-за размазывания изображения.

3.58. Нерезкость рассеяния радиационного изображения - нерезкость теневого радиационного изображения, возникающая за счет рассеяния первичного излучения в материале контролируемого объекта и (или) в материале детектора радиационного излучения.

3.59. Геометрическая нерезкость радиационного изображения - нерезкость радиационного изображения, обусловленная конечными размерами эффективного фокусного пятна источника ионизирующего излучения или геометрическими параметрами устройства, формирующего радиационное изображение.

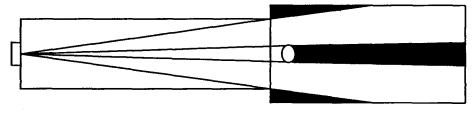

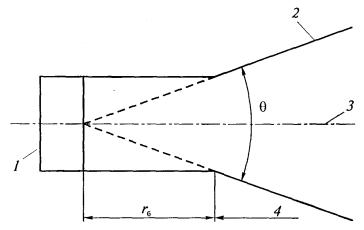

Примечание. В [2] геометрическая нерезкость (Geometric unsharpness) - нерезкость радиографического изображения, возникающая из-за конечного размера фокуса источника излучения. Ее величина также зависит от расстояний «источник-объект» и «объект-пленка». Другие названия: геометрическое размазывание или полутень.

3.60. Собственная нерезкость (Inherent unsharpness) - размазывание радиографического изображения, создаваемое фотонами излучения, которые выбивают электроны из эмульсии. Эти электроны воздействуют на зерна галогенида серебра, делая их проявляемыми.

3.61. Динамическая нерезкость радиационного изображения (Movement unsharpness) - нерезкость радиационного изображения, возникающая при относительном перемещении (в процессе преобразования изображения) источника излучения, изображаемого объекта и преобразователя изображения.

Примечание. В [2] динамическая нерезкость - размазывание радиографического или радиоскопического изображения из-за относительного движения источника излучения, объекта и детектора излучения.

3.62. Пространственное разрешение (Spatial resolution) - минимальное расстояние между элементами, которые могут быть различимы на изображении.

3.63. Коллимирование (Collimation) - ограничение пучка излучения определенной формы и определенного размера с использованием диафрагмы, изготовленной из поглощающего материала.

3.64. Коллиматор (Collimator) - устройство, изготовленное из материала, поглощающего излучение, такого, как свинец или вольфрам, сконструированное для ограничения и определения направления и сечения пучка излучения.

3.65. Держатель источника излучения (Source holder) - удерживающее, несущее или крепящее устройство, с помощью которого источник гамма-излучения (герметизированный источник) может быть зафиксирован в контейнере для экспозиции или в излучателе дистанционно управляемого устройства.

3.66. Размер источника (Source size) - размер источника излучения.

3.67. Контрастное вещество (Contrast medium) - любое вещество, твердое или жидкое, прикладываемое к радиографируемому материалу в целях увеличения радиационного контраста по всему изображению или по его части.

3.68. Радиационный контраст (Radiation contrast) - разность в интенсивностях излучения, возникающая из-за изменения способности поглощения излучения в облучаемом объеме.

3.69. Контраст изображения (Image contrast) - относительное изменение оптической плотности между двумя соседними областями на радиографическом изображении.

3.70. Контраст объекта (Object contrast) - относительная разность в прохождении излучения через две рассматриваемые зоны облучаемого объекта.

3.71. Оптический контраст (Visual contrast) - наблюдаемая разность оптических плотностей двух соседних областей освещенной радиограммы.

3.72. Контрастная чувствительность, чувствительность по толщине (Contrast sensivity, thickness sensivity) - минимальное изменение толщины образца, которое создает различимое изменение в оптической плотности радиографического или рентгеноскопического изображения, обычно выражаемое в процентах от полной толщины образца.

3.73. Разрешение изображения (Image definition) - четкость изображения деталей на радиограмме.

3.74. Улучшение изображения (Image enhancement) - любой процесс, который повышает качество изображения улучшением контраста и (или) пространственного разрешения или понижением шума. Это часто обеспечивается программой компьютера. Тогда это называется цифровой обработкой изображения.

3.75. Нерезкость преобразования радиационного изображения - нерезкость выходного изображения, возникающая при преобразовании исходного радиационного изображения двух смежных полей со скачкообразным изменением величины физического параметра изображения на границе раздела этих полей.

3.76. Обратное рассеяние (Back scatter/back scattered radiation) - часть рассеянного рентгеновского или гамма-излучения, которое эмитируется под углом, большим 90° по отношению к направлению падающего излучения.

3.77. Усилитель изображения (Image intensifier) - электронное устройство, сконструированное для получения более яркого изображения, чем изображение, получаемое при непосредственном воздействии рентгеновского излучения на флюоресцирующий экран.

3.78. Коэффициент усиления (Intensifying factor) - отношение длительности экспозиции без усиливающих экранов к длительности экспозиции с усиливающими экранами при одинаковых прочих условиях и при получении одинаковой оптической плотности.

3.79. Коэффициент усиления яркости радиационно-оптического преобразователя (Intensification factor) - отношение значения яркости выходного экрана радиационно-оптического преобразователя к значению яркости эталонного флуоресцентного экрана при одинаковых заданных условиях радиационного облучения входной плоскости преобразователя и флуоресцентного экрана.

3.80. Качество изображения (Image quality) - характеристика радиографического изображения, которая определяет различность деталей изображения.

3.81. Индикатор качества изображения (IQI) [Image quality indicator (IQI)] - устройство, содержащее набор элементов различной толщины, которое обеспечивает измерение качества изображения. Элементами этого устройства обычно являются проволочки или ступенчатый клин с отверстиями.

3.82. Показатель качества изображения, чувствительность IQI (Image quality value, IQI sensivity) - мера качества изображения, требуемая или достигнутая.

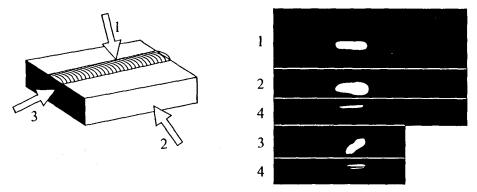

3.83. Штриховая радиационная мира - устройство, с помощью которого создается периодическое изображение в виде чередующихся необлученных и равномерно облученных полей (штрихов и промежутков), имеющих вид полос с равной шириной и параллельными границами.

3.84. Предел разрешения радиационного преобразователя - наибольшее число штрихов в 1 мм исходного изображения, созданного штриховой радиационной мирой, которое обнаруживается раздельно при анализе выходного изображения, когда условия работы преобразователя оптимальны.

Примечание. Принято обнаруживаемое число штрихов в 1 мм в «парах линий мм», считая штрих и промежуток за две линии.

3.85. Метки от давления (Pressure marks) - изменение оптической плотности радиограммы, которое может выглядеть светлым или темным, в зависимости от обстоятельств, обусловленное давлением на пленку.

3.86. Проекционное увеличение при радиационном контроле - отношение линейного размера элемента теневого изображения контролируемого объекта, сформированного точечным источником ионизирующего излучения, к размеру соответствующего элемента самого объекта.

3.87. Проекционное увеличение (Projective magnification) - увеличение размера изображения.

3.88. Способ проекционного увеличения (Projective magnification technique) - способ радиографии или радиоскопии, применяющий первичное увеличение изображения использованием расстояния между образцом и системой получения изображения.

3.89. Масштаб преобразования радиационного изображения - отношение линейного размера элемента преобразованного выходного изображения к аналогичному линейному размеру соответствующего элемента исходного радиационного изображения.

3.90. Геометрическое искажение радиационного изображения - отклонение формы преобразованного выходного изображения от формы соответствующего элемента исходного радиационного изображения.

3.91. Артефакт при преобразовании радиационного изображения - ложные элементы выходного изображения, отсутствующие в исходном изображении и возникающие в процессе преобразования исходного изображения.

Примечание. В [2] артефакт (ложный индикаторный рисунок) [artefact (false indication)] - случайный индикаторный рисунок на радиограмме, обусловленный, например, дефектами производства, обращением с пленкой, экспонированием или обработкой пленки.

3.92. Абсолютная чувствительность радиационного контроля (Absolute sensitivity of radiation inspection) - минимальное изменение значения контролируемого параметра объекта, которое может быть обнаружено с заданной вероятностью данным методом радиационного контроля.

3.93. Относительная чувствительность радиационного контроля (Relative sensitivity of radiation inspection) - отношение абсолютной чувствительности к значению контролируемого параметра, устанавливаемое в конкретной задаче радиационного контроля.

3.94. Эталон чувствительности радиационного контроля (Sensitivity standard of radiation inspection) - установленный нормативными документами по форме, составу и способу применения тест-образец с заданным распределением значения контролируемого параметра, предназначенный для определения абсолютной или относительной чувствительности радиационного контроля.

3.95. Проволочный эталон чувствительности радиационного контроля - набор проволочек установленных длин и диаметров, изготовленных с заданной точностью из материала, основа которого по химическому составу аналогична основе контролируемого материала.

3.96. Многопроволочный индикатор качества изображения (Duplex wire image quality indicator) - индикатор качества изображения, специально сконструированный для оценки общей нерезкости радиографического изображения и состоящий из множества пар проволочных элементов, изготовленных из металла высокой плотности.

3.97. Канавочный эталон чувствительности радиационного контроля - пластина с канавками установленных форм и размеров, изготовленная с заданной точностью из материала, основа которого по химическому составу аналогична основе контролируемого материала.

3.98. Пластинчатый эталон чувствительности радиационного контроля - пластина с цилиндрическими отверстиями установленных форм и размеров, изготовленная с заданной точностью из материала, основа которого по химическому составу аналогична основе контролируемого материала.

3.99. Радиография (Radiography) – получение радиограмм на прочном основании, предназначенном для получения изображения.

3.100. Гамма-радиография (Gamma-radiography) – радиография с использованием источника гамма-излучения.

3.101. Гамма-излучение (Gamma-rays) – электромагнитное ионизирующее излучение, эмитируемое особыми радиоактивными материалами.

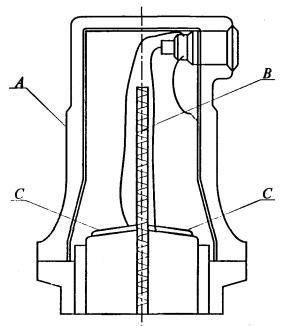

3.102. Источник гамма-излучения (Gamma-ray source) – радиоактивный материал, герметизированный в металлическом контейнере.

3.103. Радиоизотоп (Radioisotope) – изотоп элемента, обладающий свойством спонтанного эмиттирования частиц, гамма-излучения или рентгеновского излучения.

3.104. Период полураспада (Half life) – время, в течение которого активность радиоактивного источника спадает до половинного значения.

3.105. Удельная активность (Specific activity) – активность на единицу массы радиоизотопа.

3.106. Контейнер источника гамма-излучения (Gamma-ray source container) – контейнер, изготовленный из материала большой плотности, имеющий стенки толщиной, достаточной для сильного снижения интенсивности излучения, эмитированного источником, для обеспечения безопасности обращения с ним.

3.107. Радиометрический метод неразрушающего конроля – метод радиационного НК, основанный на измерении одного или нескольких параметров ионизирующего излучения после его взаимодействия с контролируемым объектом.

3.108. Радиографический метод неразрушающего конроля – метод радиационного НК, основанный на преобразовании изображения контролируемого объекта в радиографический снимок или записи этого изображения на запоминающем устройстве с последующим преобразованием в световое изображение.

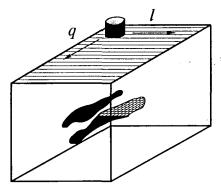

3.109. Компьютерная томография (КТ) [Computerized tomography (СТ)] - процедура, при которой изображение детали в выбранной плоскости, перпендикулярной оси образца, рассчитывается исходя из большого количества измерений поглощения рентгеновского излучения, выполненных по разным направлениям, перпендикулярным оси.

Примечание. Это компьютерная аксиальная томография. Возможны и другие способы выполнения томографии.

3.110. Метод радиационной интроскопии - метод радиационного НК, основанный на преобразовании изображения контролируемого объекта в световое изображение на выходном световом экране радиационно-оптического преобразователя, причем анализ полученного изображения проводится в процессе контроля.

3.111. Метод радиационно-структурного анализа - метод определения структуры материала контролируемого объекта, основанный на регистрации и анализе ионизирующего излучения, испытавшего дифракцию на контролируемом объекте.

3.112. Метод радиационно-спектрального анализа - метод определения химического состава материала контролируемого объекта, основанный на анализе спектрального распределения ионизирующего излучения, возникшего в результате взаимодействия первичного ионизирующего излучения с контролируемым объектом.

3.113. Радиационная толщинометрия - радиометрический метод НК, предназначенный для измерения толщины или поверхностной плотности материала и основанный на измерении параметров ионизирующего излучения, возникающего в результате взаимодействия первичного ионизирующего излучения с контролируемым объектом.

3.114. Флюорография - радиографический метод НК, основанный на фотографировании светового изображения, возникшего на флюоресцентном экране или на выходном экране радиационно-оптического преобразователя.

3.115. Радиоскопия (Radioscopy) - получение видимого изображения с помощью ионизирующего излучения на детекторе излучения, таком, как флюоресцирующий экран, и выводимого на экран телевизионного монитора.

3.116. Электрорадиография - радиографический метод НК, основанный па преобразовании исходного радиационного изображения в рельефе электрического потенциала на полупроводниковой пластине с последующим преобразованием рельефа электрического потенциала в радиографический снимок.

3.117. Кинорадиография - радиографический метод НК, предусматривающий получение через разные промежутки времени упорядоченной последовательности исходных радиационных изображений и соответствующих им радиографических снимков на кинопленке и предъявление наблюдателю выходных изображений с частотой, превышающей критическую частоту слияния мельканий.

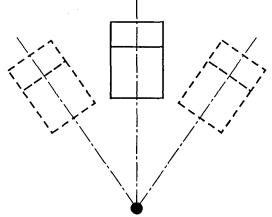

3.118. Стереорадиография - радиографический метод НК, основанный на анализе стереопары радиографических снимков, полученных в результате преобразования двух исходных радиационных изображений, созданных двумя пучками ионизирующих излучений, между осями которых имеется заданный угол.

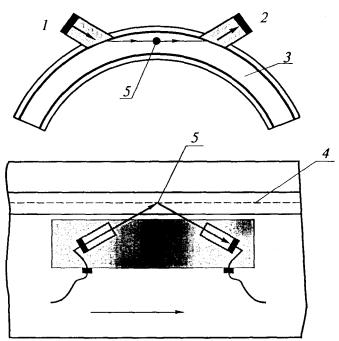

Примечание. В [2] стереорадиография (Stereo radiography) - получение пары радиограмм, пригодных для стереоскопического рассмотрения.

3.119. Цветовая радиография - радиографический метод НК, при котором градации параметра исходного радиационного изображения воспроизводятся в виде градации цвета.

3.120. Радиационная томография - радиографический метод НК, позволяющий получать послойно изображения контролируемого объекта.

3.121. Вычислительная томография - радиографический метод НК регистрации ослабления потока энергии одного (или нескольких) пучка ионизирующего излучения, перемещающегося таким образом, чтобы оси этого пучка лежали в одной плоскости (плоскости контроля), с последующим расчетом на ЭВМ линейных коэффициентов ослабления для элементов заданного сечения и выводом светового изображения, соответствующего распределению указанных коэффициентов.

3.122. Флюороскопия - метод радиационной интроскопии, в котором в качестве радиационно-оптического преобразователя используется флюоресцентный экран.

Примечание. В [2] флюороскопия (Fluoroscopy) - получение видимого изображения на экране, флюоресцирующем под воздействием рентгеновского излучения, для непосредственного наблюдения изображения.

3.123. Стереорадиоскопия - метод радиационной интроскопии, основанный на анализе в процессе облучения стереопары выходных изображений, полученных в результате преобразования двух исходных радиационных изображений, создаваемых двумя пучками ионизирующих излучений, между осями которых имеется заданный угол.

3.124. Микрофокусная радиография (Microfocus radiography) - радиография с использованием рентгеновской трубки, имеющей очень малый эффективный размер фокуса - менее 100 мкм. Обычно применяется для непосредственного геометрического увеличения изображения при проектировании.

3.125. Компенсатор ионизирующего излучения - дополнительное поглощающее тело (вещество), вводимое в зону рабочего пучка ионизирующего излучения в целях улучшения условий регистрации радиационного изображения и анализа выходного изображения контролируемого объекта.

3.126. Компенсатор (Equalizing filter, beam flattener) - устройство, используемое для выравнивания интенсивности излучения по сечению пучка первичного рентгеновского излучения в мегавольтовой радиографии, что позволяет увеличить полезный размер поля.

3.127. Краевой компенсатор (Edge-blocking material) - материал, располагаемый вокруг объекта контроля или в полостях для получения более равномерного поглощения в целях уменьшения влияния внешнего рассеянного излучения и для предотвращения местной переэкспозиции, например мелкая свинцовая дробь.

3.128. Блокирующий материал (Blocking medium) - материал, используемый для уменьшения влияния рассеянного излучения на пленку или на приемник изображения.

3.129. Фильтр ионизирующего излучения - совокупность поглощающих сред, предназначенных для изменения энергетического спектра ионизирующего излучения.

3.130. Фильтр (Filter) - однородный слой материала, обычно более высокого атомного номера, чем материал образца, располагаемый между источником излучения и пленкой в целях повышенного поглощения более мягкого излучения.